|

Caledonian FIREGUARD Cables

CABLE CONSTRUCTION

FIREGUARD cables are constructed in the following typical design:

1. Solid/stranded annealed copper conductor

2. Glass mica tape/silicone rubber as flame barrier

3. XLPE/PVC as insulation

4. Normal or Flame retardant FRPVC as sheath

FIREGUARD cables are offered in either single core, multicore or multi-pair constructions.

The insulation material is usually PVC with different levels of fire retardance properties to meet different stringent environment requirement. The cables may be armoured or braided, with or without metallic screen, depending on different applications.

INTERNATIONAL STANDARD

The FIREGUARD cables manufactured by Caledonian comply with either one or combination of the following standards.

IEC 60332-1

IEC 60332-3C

|

|

|

PRODUCTS

Flame Retardant offshore & Marine Cables(BS 6883&BS7917)

MV Flame Retardant Power & Control Cables

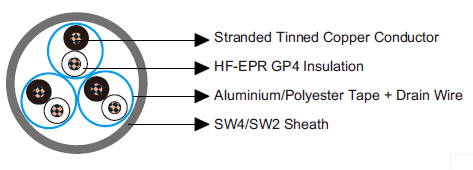

150/250V HF-EPR Insulated, SW2/SW4 Sheathed, Individually Screened Unarmoured

Application

These elastomeric insulated cables are designed for fixed wiring in ships and on mobile offshore units, suitable for use in instrumentation, lighting and control circuits.

Standards

BS 6883

IEC 60332-3A Flame retardant

IEC 60754-1; IEC 60754-2 Corrosivity

IEC 61034-2 Smoke density

Cold bend and impact (-40°C) (on request)

CSA C22.2 No. 38-95 (on request)

Construction

Conductor: Tinned copper wire stranded circular cl. 2 BS 6360/IEC 60228.

Insulation: HF-EPR GP4 according to BS 7655 1.2.

Lay-up: Pairs, triples, quads.

Individual Screen: Aluminium/polyester tape + drain wire tinned copper.

Sheath: Halogen free thermosetting compound SW4 according to BS 7655 2.6 or reduced halogen thermosetting compound SW2 according to BS 7655 2.6.

Mechanical and Thermal Properties

Minimum Internal Bending Radius: 8×OD

Temperature Range: -40℃ ~ +90℃

Download details in PDF

Download details in Word

|

|