|

Caledonian fireflix Cables

CABLE CONSTRUCTION

fireflix cables are constructed in the following typical design:

1. Solid/stranded annealed copper conductor

2. Glass mica tape/silicone rubber as flame barrier

3. XLPE/silicone rubber as insulation

4. LSZH/Flame retardant RPVC as sheath

fireflix cables are offered in either single core, multicore or multi-pair constructions.

The insulation material can be elastomeric (EPR, SR), thermosetting (XLPE, LSZH) or thermoplastic (EVA, LSZH) to meet different stringent environment requirement. The cables may be armoured or braided, with or without metallic screen, depending on different applications.

INTERNATIONAL STANDARD

The fireflix cables manufactured by Caledonian comply with either one or combination of the following standards.

BS 6387

IEC 60331

IEC 60332-1

IEC 60332-3C

IEC 61034-1/2

IEC 60754-1

|

|

|

PRODUCTS

Fire Resistan NEK606 Water Blocked Offshore & Marine Cable

Water Blocked Fire Resistant Instrumention Cables

Water Blocked S3 or S3/S7 BFOU(i) 250V

Applications

These cables are fire resistant, flame retardant, low smoke,halogen free and mud resistant, used for instrumentation, communication, control and alarm systems.

Standards

IEC 60092-376 IEC 60092-351

IEC 60092-359 IEC 60332-1

IEC 60332-3-22 IEC 60754-1,2

IEC 61034-1,2 NEK 606:2004

VG 95218 part 29

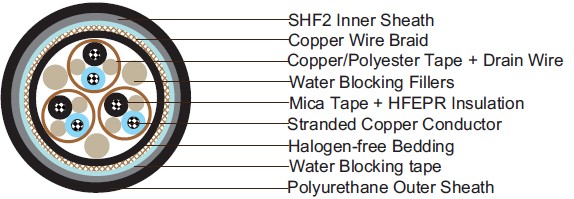

Construction

Conductors: Circular tinned annealed stranded copper wire to IEC 60228 class 2.

Insulation: Mica tape + Halogen free EPR compound.

Twinning: Colour coded cores twisted together.

Filler: Water blocking fillers, if required.

Individual Shielding: Each pairs/triples are screened by copper backed polyester tape in contact with a stranded tinned copper drain wire and wrapped with polyester tape. Pairs/triples are numbered with numbered tape or by numbers printed directly on the insulated conductors.

Filler: Water blocking fillers, if required.

Bedding: Halogen free compound, PETP wrapping tape will be applied over the bedding, if required.

Armour: Tinned copper wire braid, PETP wrapping tape will be applied over the braiding, if required.

Water Blocking Elements: Water blocking tape and strings for providing longitudinal water tightness.

Inner Sheath: Halogen free thermosetting compound, SHF2 (for TYPE S3). Halogen free MUD resistant thermosetting compound, SHF MUD (for TYPE S3/S7), coloured grey (blue for intrinsically safe).

Outer Sheath: Polyurethane for providing transversal water tightness, PE is optional,but can not meet low smoke standard.

Download details in PDF

Download details in Word

|

|